WHITEPAPERS

Rapid Prototyping for IoT: What, Why, and How

Validate your IoT solution, deliver value quickly, and reduce surprises with rapid prototyping for IoT. Learn the what, why, and how in this guide.

Over the next decade, IoT technology is projected to fuel substantial growth in the economy, particularly within the consumer, commercial, and industrial sectors.

Particularly when we look at IoT-connected machines, “IoT devices used by manufacturing facilities, companies, organizations, governments, utilities, and defense facilities to improve operations,” we see huge predicted growth. The market for IoT-connected machines is projected to mushroom to $510.85 billion by 2029, representing a CAGR (compound annual growth rate) of 19.2% over seven years.

What’s more, companies selling IoT devices to consumers aren’t far behind in terms of estimated growth. The projection for the consumer IoT market is a CAGR of 17.52% over the next eight years. Within this market, home automation will likely account for the largest share of growth.

It should come as no surprise, then, that we’re witnessing a slew of companies eagerly rolling out IoT products and connected systems for the first time. We’re also seeing lots of companies with pre-existing IoT capabilities expand their product lines. These trends make sense; if you have a concept for an IoT solution that your market will love — and pay significantly more for — why leave money on the table?

But before you can bring your solution to life, you’ll need to test, iterate, and validate the solution — all prior to full-scale production. There may be some aspects of your solution that can be tested via simulation with digital twin simulations, but ultimately, you’ll need to test it in real-world environments.

Enter rapid prototyping.

What Is Rapid Prototyping?

Rapid prototyping for IoT refers to quickly creating and testing a preliminary “looks like” and/or “works like” version of a proposed IoT solution.

IoT prototypes are used to evaluate the device or system’s feasibility, functionality, and usability before committing to full-scale production. The goal is to quickly iterate through different designs and configurations to arrive at a final solution.

Benefits of Rapid Prototyping for IoT

IoT projects are complex and unpredictable, and, as any engineer knows, the more surprises that pop up, the quicker the cost can skyrocket. Rapid prototyping helps cut down on the number of surprises.

Prototypes are important for IoT products and connected systems because they allow for early testing of business value, technology, user feedback, and security. Armed with these insights, product owners can change their priorities and quickly begin iterative testing, learning, and modification. Addressing potential issues before the solution is finalized and put into full-scale production ensures that it’s reliable, efficient, and user-friendly.

Prototyping also allows for testing the end-to-end solution, including the integration of the hardware, software, data collection, communication protocols, and machine learning models.

Real data — early in the project — is particularly valuable.

If you’ve ever built machine learning models outside of a classroom, you know that the data you use can make or break your models. That’s why it’s so important to get real data as early as possible, so that your hardware and algorithms can grow together.

This goes hand in hand with the emerging paradigm in the AI field called data-centric AI, which focuses on systematically engineering your data to generate better models. The traditional model-centric AI approach, on the other hand, takes the data as given and then focuses on optimizing the modeling methods.

If you integrate your hardware and algorithms early on in the project with rapid prototyping, you’ll save yourself a lot of time and money in the long run.

Imagine spending months perfecting your hardware before your data science team even starts working on the algorithms. That could result in many more months optimizing modeling methods that could have been avoided if you had made a small change to your hardware and data earlier in the project.

Ultimately, failing to get the level of accuracy you want from your hardware could lead to a major redesign later in the project, which nobody wants. Using rapid prototyping to get real data early is key.

How Is Prototyping an IoT Solution Different From Other Use Cases?

In short, there’s significantly more to build and test for an IoT solution than for a standalone piece of hardware or software.

IoT solutions involve multiple components and associated technologies, such as sensors, low-power operation measurement, wireless connectivity, cloud configuration, and user interfaces for web/mobile apps.

Additionally, IoT prototyping often involves techniques and tools meant to accelerate the process, such as off-the-shelf parts, ready-to-use solutions, and broad sets of libraries supporting various sensors and actuators, wireless components, communication protocols, and processing algorithms. These techniques are used to build a functional prototype faster and to gather early feedback from users and stakeholders, minimizing the risks associated with large, complex systems.

How Do You Create Prototypes of IoT Products or Connected Systems?

There’s no one-size-fits-all answer to this. Ultimately, it depends on the solution you’re building. However, there are approaches that apply to virtually any IoT project, so we’ll cover those highlights here.

Do your homework.

Before prototyping begins, you’ll need to complete in-depth research, planning, and initial design work.

Part of this due diligence is making sure your intended solution will actually meet user needs. Our design team relies on customer journey mapping for these critical insights.

Another consideration is determining the regulatory compliance standards your solution will be subject to.

Embrace working in an agile environment.

Agile is one of the keys to successful rapid prototyping. To move rapidly — and most effectively — embrace the Agile project methodology.

Note that there’s a difference between “Agile” and “agile.” We make that distinction because the strictest interpretation of the Agile methodology may not work for a team that’s used to a Waterfall approach. However, you can adopt a hybrid approach that embraces key aspects of Agile and move forward with an agile mindset — even with hardware prototyping. Here are some of the most important aspects of Agile you need to adopt if you want to prototype rapidly.

- Choose the shortest path forward.

Stay focused on the goal. Cut out feature bloat so you can keep moving quickly. This applies to hardware as well. Multiple hardware iterations will allow you to build additional hardware features later.

- Parallelize work streams.

Team members from hardware, software, data science, and design need to communicate seamlessly and work together in parallel to accomplish project-level goals.

- Work atomically.

It’s a lot easier to build a larger system composed of individual, independent pieces than it is to craft each component concurrently. Break down, review, and deliver your work in the smallest chunks possible.

Choose the right design & communication tools.

Choosing smart design and communication tools will make collaboration, documentation, organization, and alignment easier.

Case in point?

There are only so many design ideas a mechanical engineer can come up with using traditional CAD software. Most of them are unimaginative, which can lead to overbuilt, cumbersome products. You can use generative design to meet this challenge.

Generative design uses mathematical optimization combined with finite element analysis to automatically create optimal part geometries. It can create hundreds of the lightest, strongest, most intricate designs as an output.

We use Onshape as our CAD software of choice. Onshape uses an application called ParaMatters to construct hundreds of generative designs. A single engineer simply could not conceive of these types of designs on their own.

Be prepared with tricks of the trade for mechanical and electrical engineering.

With thousands of hours of IoT engineering under our belts, we’ve developed proven processes for quickly engineering IoT prototypes. The following list covers key points, but isn’t exhaustive.

- Leverage ultra-localized production.

Using 3D printers, printed circuit board (PCB) mills, and laser cutters to create many of your initial prototypes can reduce the barrier to building a prototype.

- Take advantage of onshore rapid prototyping for custom PCBAs.

There are plenty of short-turn-time PCBA manufacturers in the market. If you familiarize yourself with their design rules, you can get fully custom PCBAs in as little as a week.

- Consider modularized RF components for prototyping.

While they might not be the most cost-effective in the long run, they can eliminate weeks of development time in the shorter term.

- Leverage development boards and kits that are well-suited for IoT prototypes.

Board and kit availability fluctuate fairly often. You can find our most recent recommendations for IoT dev boards and kits in this post.

- Make Your Own PCBAs

If you want to make your own prototypes, 3D printers and desktop computer numerical control machines (CNCs) can provide you with a quick feel of your product.

Test your prototypes early and often across the entire team.

Whenever possible, engineers, designers, program managers, leaders, and users should be testing along the way. The more you allow people to experiment with the product, the more you’ll be able to identify gaps that need filling.

How Do You Test IoT Prototypes?

There are several ways to test IoT prototypes, depending on the specific device or system being developed. Some common testing methods include:

- Functional unit testing: This involves testing the basic functions of the device to ensure that it works as intended. This can include testing sensors, actuators, and connectivity.

- Performance testing: This involves testing the device under different conditions to ensure that it can handle different loads, environmental conditions, and usage scenarios. This can include testing for power consumption, temperature, and other factors.

- Security testing: This allows product developers to ensure all data transmitted and stored within the product is secure. This can include testing for vulnerabilities and penetration testing.

- User testing: This involves testing the device with real users to get feedback on the usability, design, and overall user experience.

- Integration testing: This involves testing the device with other devices and systems to confirm that it can communicate and integrate properly with other devices, networks, and platforms.

It’s important to test not only in the lab, but also in real-world conditions. Also, be sure to test in all the different stages of the development process in order to guarantee the quality of the final solution.

Rapid Prototyping for IoT: Real-World Results With Tattlebox

You may be thinking, “All of this sounds interesting in theory, but how does it work in practice?”

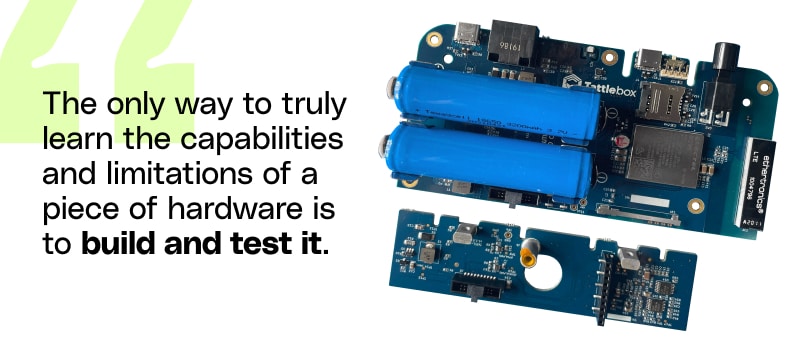

Tattlebox needed to quickly design and build a low-power security device that could track large, mobile assets and update owners from anywhere in the world. They came to Very because they wanted a partner who could quickly and efficiently design and prototype functional hardware.

After engaging a custom PCBA manufacturer with rapid turn capabilities (and firing up the 3D printers in our engineers’ home labs), our team generated a functional prototype for Tattlebox.

Final Thoughts

Ultimately, rapid prototyping leads to better IoT solutions. By breaking down each component and creating multiple successions of rapid prototypes, developers can test the functionality of their device or system, identify any design flaws, and make improvements before the final product is released to the public. How you prototype a product or solution will vary depending on the use case, but if you follow the best practices for rapid prototyping, you’ll be heading in the right direction.