BLOG

Rapid IoT Prototyping: 3 Keys to Success

Have a great idea for an IoT product or system? An important step to launching successfully will be creating early prototypes that yield critical learning. Don’t take the leap without a plan for IoT prototyping — rapidly. Rapid prototyping will ensure the product works well before landing in the hands of your clients.

Why does rapid prototyping for IoT matter?

The short answer is that rapid prototyping is a catalyst to going to market, allowing project owners to lower risk and gain visibility into a product’s ROI before it enters the production stage. The design and development teams can validate their designs, experiment with different configurations and components, and identify potential problems or limitations before moving into the production phase.

IoT projects are complex, unpredictable, and riddled with risk. That’s why project owners need to de-risk projects early; there’s no use sinking significant funds into the project until you’re confident the product will work. Rapid prototyping enables you to validate your project idea before you reach a point of no return.

Moreover, stakeholders need to prove the value proposition quickly. That means project owners must be able to generate actual data to create actionable insights, align with customers through testing, and adapt as needed while the design is fluid. Rapid prototyping makes that possible.

We’ve spent years building early prototypes at Very. In that time, we’ve identified three crucial keys to success for rapid IoT prototyping:

- Leveraging the Agile methodology

- Testing early and often

- Using the right tooling

Let’s dive in.

#1: The Agile Methodology

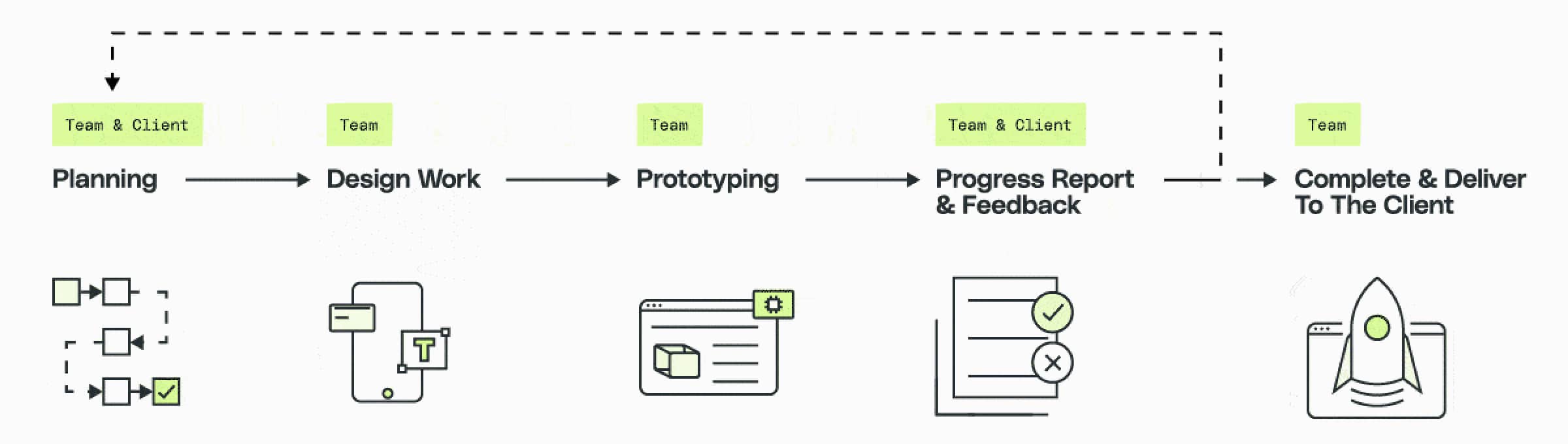

The Agile methodology involves small, cross-functional teams working closely to deliver minimal viable products (MVPs) in short, iterative cycles. Using the Agile approach consistently for IoT prototypes, we’ve gained considerable knowledge on how it empowers success. Here are some of our insights.

Choose the shortest path forward.

Moving quickly sometimes means making hard decisions. Stay focused on the goal and cut out feature bloat so you can keep moving quickly. This applies to hardware as well. With multiple hardware iterations, you can build additional hardware features later.

Don’t paralyze; parallelize.

Siloing teams by discipline will paralyze your development. Team members from hardware, software, data science, and design need to communicate continually and work together in parallel to accomplish project-level goals.

Part selection, for example, is often completed without firmware input. This can cause issues later when the firmware engineer discovers that integrating a specific part is a huge lift, and that using a similar part would have been much easier. Involving the firmware engineer during the part selection process avoids that problem altogether, saving time and costs in the long run. By eliminating silos, teams can uncover issues sooner and solve them collaboratively, leading to better, faster solutions.

Get the prototypes to everyone.

Your electrical engineer isn’t the only one who needs prototypes. Firmware engineers, mechanical engineers, program management, and leadership should also have access to them.

It’s even better to get prototypes in front of potential users to get feedback early on. Seek to gather perspectives from every angle. Let your leadership tinker around with and break the prototype. The more you allow people to experiment with the product, the more you’ll be able to identify gaps that need filling.

Be atomic.

What we mean is: think small, and then think even smaller.

It’s a lot easier to build a larger system composed of individual, independent pieces than it is to craft each component concurrently.

Break down, review, and deliver your work in the smallest chunks possible. Think outside the box when it comes to breaking down work. If you’re reviewing an entire board, you aren’t thinking small enough. Review just the power supply, just the core microcontroller components, just the memory storage, and just the sensor layout. Reviewing and delivering in smaller chunks gives you a higher chance of catching and fixing issues early on.

Ultimately, building atomically enables tighter feedback loops between disciplines and, most importantly, with the customer. This early feedback doesn’t just correct false assumptions — it also unlocks hidden value and ushers the product to market as quickly as possible.

#2: Test Early & Often

If you’re building atomically, you can — and should — be testing early and often.

You won’t realize a product’s value until it’s tested in real-world applications. So, begin testing as early as possible to identify issues before you’ve invested too heavily in decisions that are hard to undo. Test often to keep progress continuous and consistent.

As you’re building the test plan for the prototype keep these tips in mind:

- Test both in the real world and the lab.

- Don’t rely solely on yourself for testing. Get the prototypes in the hands of the expected users if possible.

- Think about all the ways the prototype might fail, and test those scenarios.

- Use effective testing tools.

You can find more details on recommendations for IoT user testing in this article.

#3: Use the Right Tooling

Excellent design and communication tools are crucial.

Smart design tools enable teams to collaborate seamlessly across borders and time zones. Use these to your advantage when rapid prototyping for IoT. For example, cloud-based CAD software like OnShape allows collaborators to access and edit files from any device. Popular versioning and file storage tools like git/GitHub store and version both software and hardware designs, functioning as a lightweight product data management (PDM) system without excessive overhead.

Additionally, user-friendly communications platforms like Slack, Microsoft Teams, and Discord help organize information and keep teams aligned.

Use ultra-localized production to your advantage.

You can build a lot from the comfort of your own desk. Leveraging 3D printers, printed circuit board (PCB) mills, and laser cutters to create many of your initial prototypes can reduce the barrier to building a prototype. But don’t forget to complement your cutting-edge tech with “old school” tooling, such as high-quality soldering irons, reflow ovens, and hot air stations. Combining these tools can help you fabricate and rework most basic circuit boards, significantly reducing time spent making prototypes so you have more time to test them.

Onshore rapid prototyping for custom PCBAs.

There are plenty of short-turn-time PCBA manufacturers in the market. If you familiarize yourself with their design rules, you can get fully custom PCBAs in as little as a week. This might not be cheap, but consider this as investing one dollar today to save 10 dollars tomorrow. Companies like Circuit Hub and Screaming Circuits are excellent options for getting prototype boards fast.

Leverage the right parts, both off-the-shelf and other “shortcuts” to move faster.

RF modularized components are great tools for rapid IoT prototyping. While they might not be the most cost-effective in the long run, they can eliminate weeks of development time in the shorter term. They eliminate the need for complicated layout and tuning of RF front ends; just drop it on your board and go.

Top Development Boards & Kits for Rapid IoT Prototyping

Among the many boards and kits we’ve used, recently the following boards and kits have worked quite well for rapid prototyping.

- nRF52840 DK Single Board Development Kit

The nRF52840 DK is great for BlueTooth® and battery-powered devices. The inclusion of standard hardware debugging and prototyping interfaces allows you to write firmware against the dev kits, expediting time to market.

- i.MX6ULL Development Kit

The i.MX6ULL is great for gateway applications, mainly because it provides reference design files that make it easier and faster to debug custom hardware.

- mikroBUS™ Click Boards

mikroBUS™ Click Boards are a standardized hardware interface for thousands of varying components. It’s excellent for rapid prototyping both hardware and firmware.

They contain sensors, radios, Ethernet interface chips, and tons of other types of devices. Ultimately, mikroBUS click boards make it possible to easily interface with these external devices to start testing hardware and firmware earlier.

Make Your Own PCBAs

If you want to make your own prototypes, 3D printers and desktop computer numerical control machines (CNCs) can provide you with a quick feel of your product. Plus, if you have 3D printers available in-house, you can quickly iterate and test new features without waiting on a third party to build them for you.

At Very, we use 3D printers to prototype mechanical parts and the desktop CNCs to prototype circuit boards.

Consider the Formlabs SLA Printer (3D)

Using a high-resolution machine like the Formlabs printer allows you to test and iterate complex geometries quickly.

Consider the Nomad 3 CNC

A PCB mill can make your own two-layer boards from copper clad very quickly, enabling rapid prototyping of design chunks. This yields very strong boards that can handle a surprising amount of power.

Examples of Rapid Prototyping

Now that you understand the three keys to success for rapid prototyping, what does it look like in action?

Here’s a real-world example:

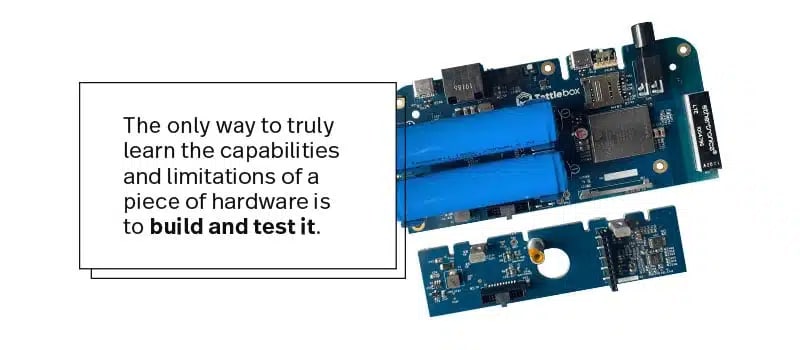

Tattlebox: Rapid IoT Prototyping for a Low-Power Security Device

After engaging a custom PCBA manufacturer with rapid turn capabilities (and firing up the 3D printers in our engineers’ home labs), our team generated a functional prototype for Tattlebox in just seven weeks. This prototype allowed Tattlebox to execute their business logic on real hardware and quickly improve their firmware. Based on Tattlebox’s progress, Very made additional hardware changes to finalize the board design. This iterative process created a positive feedback loop – a virtuous circle of product improvement.

While developing the first version of the board, a chip went out of stock. Our senior embedded electrical engineer on the project “hacked in” a devkit to the first version of the board in less than three hours. Tattlebox used the adapted V1 board to modify the firmware and prove the viability of the replacement chip. Very then updated the V2 board design to use the new part, effectively solving the chip shortage problem.

You won’t find this product on store shelves yet, but there’s a good reason for that. Very’s rapid prototyping enabled Tattlebox to test assumptions, generate data, and get the devices into the hands of potential customers quickly. Based on customer feedback, Tattlebox discovered that a few additional tweaks would allow them to pivot into a broader – more lucrative – market. So instead of launching a limited product, Tattlebox opted to save money on this production run and launch with a revamped offering targeting this newly-identified, more profitable market segment.

LEARN MORE: Find out how, in just 15 weeks, Very created Tattlebox’s first prototype using agile methodologies.

Final Thoughts

Rapid prototyping is a critical process in the development of IoT products. It allows project managers and developers to test and refine their ideas quickly and efficiently, identify potential issues, and lower the risk of failure before investing significant resources in production. Rapid prototyping is especially important in the unpredictable IoT ecosystem, where stakeholder buy-in and validation of the value proposition are crucial. By leveraging the Agile methodology, testing early and often, and utilizing the right tools, project owners can ensure that their IoT products are well-designed, functional, and exceed expectations across the board. For more detail on this topic, read our whitepaper on rapid prototyping.