BLOG

Very Engineers Combat COVID-19 in OpenVentilator Project

With the spread of COVID-19 pushing healthcare systems to their breaking point around the world, the need for ventilators to support critically ill patients has never been greater – yet the current demand far outweighs the global supply.

In light of this, medical device company Medtronic recently released the design files for their Medtronic PB560 ventilator, originally released in the mid-2000s, so that other engineers and manufacturers could increase and expedite ventilator production globally.

While the release of the FDA-approved files marks a watershed moment in the battle against the novel coronavirus pandemic (starting a ventilator design from scratch and meeting FDA compliance standards would take years), there’s more work to be done to make the files usable for the people who need them most.

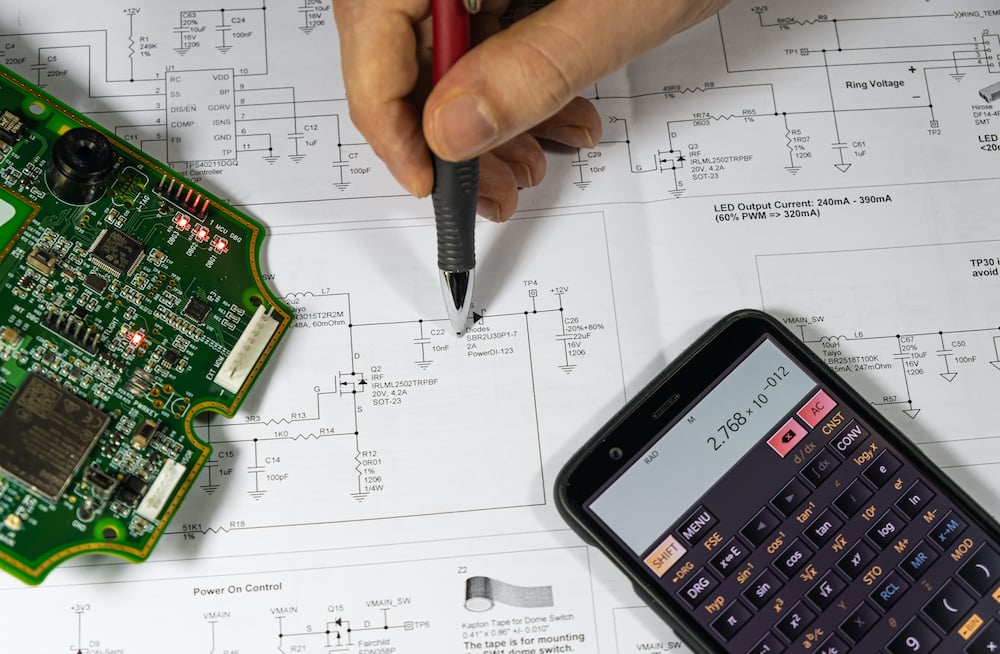

That’s where the KiCAD Medtronic OpenVentilator project comes in. Spearheaded by Lead Developer at KiCAD Services Corporation Seth Hilbrand, more than 50 engineers from around the globe are combining their skillsets to modernize the files and make them more accessible. They’re also collaborating with manufacturing entities to make it possible for communities in need to get access to the life-saving machines.

How Very Engineers Are Making an Impact

After spotting the call for makers to join the OpenVentilator project shared online, Very engineers Adam Drewery and Melvin Aguirre jumped at the opportunity to get involved.

Upon joining the group, Adam and Melvin spotted key areas where they could assist not only from a technical standpoint but from a project management perspective as well.

“Having already worked in a remote environment, we saw an immediate spot for us to come in and contribute our processes to help provide a framework for the group to work with,” says Adam, an embedded/electrical engineer at Very.

Melvin, one of our IoT embedded software engineers, added, “It’s not only remote, but it’s also asynchronous communication. There are people in Poland, Italy, the UK, Argentina, and more, and we’re basically tag-teaming some of these things,” he says. “At the end of the night, we say, ‘Okay, this is what I’ve done, I’ve pushed my work, and now someone else can take it on.'”

Both Adam and Melvin shared documentation with the OpenVentilator community of best practices for electrical and embedded engineering, respectively, based on their experience working on multidisciplinary IoT projects at Very. In particular, Melvin added that Very’s retrospective approach of in-depth debriefing after every sprint and project has helped them create living processes for the OpenVentilator project.

“This Is the Work We’d Be Doing Anyway”

Melvin and Adam are able to devote a portion of their weekly work hours to the OpenVentilator project through Very’s “Teach, Learn, Do” framework. Under this model, Very provides billable employees with the opportunity to spend up to 7 work hours per week on innovative personal and company projects that help them to learn new things or share knowledge with others.

Although they’re glad to work for a company that allows flexibility for projects like this, both Adam and Melvin stressed that even if they didn’t, they would have made time for OpenVentilator regardless.

“I have family in healthcare, so I’ve been wracking my brain for ways I could help,” Adam says. “I felt like there was more I could be doing to help in any way. Then Melvin found this project and shared it with me, and I realized that I could use the skills and experience I already have, which are relatively rare, to help in a unique way.”

Inspired by the Open-Source Community

One of the most inspiring things about the project, both Adam and Melvin said, is getting to see all the different ways people are contributing and collaborating. Many engineers on the project are not only leveraging their expertise but also stepping out of their comfort zones to learn new tools so that they can work together more effectively.

For example, in the hardware world, version control in Git is “well outside of the norm,” according to Adam. Yet the group persists in learning it because they’re committed to a larger goal, with Adam and others who are more experienced offering advice where it’s needed. Overall, they’re doing well because of their willingness to partner with each other.

“Something I’ve learned at Very that I’ve found myself bringing to the OpenVentilator project is taking the time to pair with people on challenges,” Melvin says. “We have a culture where, if someone is struggling, we’ll hop on a quick Zoom call to solve the problem, and it helps everyone work more efficiently. I’ve been doing this on OpenVentilator and it’s allowed me not only to teach people but learn from them as well.”

The open-source nature of the project also helps improve the quality of the product. With fewer constraints than you’d have in a traditional development environment, engineers have the freedom to think outside of the box and come up with creative solutions. Additionally, when everyone can see everyone else’s work, you’re more likely to catch errors and potential vulnerabilities.

“Sometimes, you get blinders on because you’ve been staring at something for so long,” Melvin says. “Having to show someone else your work and explain what you did helps you to realize whether your approach was correct or not. It’s a great opportunity to provide and receive constructive feedback as well.”

How Will OpenVentilator Meet Global Needs?

The OpenVentilator project presents a unique challenge for engineers because it’s time-sensitive, requires extreme accuracy, and ultimately because the lives of real people across the globe may depend on the project’s success.

What if the ventilators aren’t done in time? What if the team can only help get 1,000 of them manufactured?

Adam notes that 1,000 ventilators will still be highly valuable – even if they’re not all manufactured by the time the first wave of the pandemic passes. The ventilators that have already been distributed are being used much more heavily than normal, and will thus need replacing sooner. We also don’t know what the rest of 2020 has in store when it comes to COVID-19.

Melvin, whose roots are outside of the United States, also reminds us that it’s all too easy to adopt a US-centric view of what is actually a global pandemic. In Latin America, for example, the curves of infection are only just beginning, so there will soon be a need for ventilators there.

How Can You Help?

If you or someone you know is interested in joining the OpenVentilator project, you can get involved here. Specifically, the team is in need of mechanical engineers and people who can help with firmware support, but they are happy to have help from anyone with relevant technical knowledge or expertise.