BLOG

What Makes A Smart Warehouse Smarter? Optimized IoT Connectivity

If you’ve read our ultimate guide to IoT connectivity, you know that connectivity allows devices to connect to the internet, other devices, or a central hub to transmit and receive data. And if you run a smart warehouse, you know that optimizing that connectivity to work in alignment with your business goals is key to keeping costs low and operational efficiencies high.

IoT connectivity refers to the network of physical devices, vehicles, and other items embedded with sensors, software, and similar technologies that facilitate the exchange of data with other devices and systems over the Internet. In smart warehouses, applications can range from simple temperature and humidity sensors to sophisticated inventory management systems and autonomous robots.

In this article, we’ll explore some key considerations for smart warehouse managers to keep in mind when configuring their IoT connectivity architecture.

Key Considerations: IoT Connectivity in Smart Warehouses

The right IoT connectivity framework makes all the difference for seamless operations and scalability in smart warehouses. As warehouses become more sophisticated, integrating IoT devices for various functions—from inventory management to automated material handling—requires robust, flexible connectivity infrastructure.

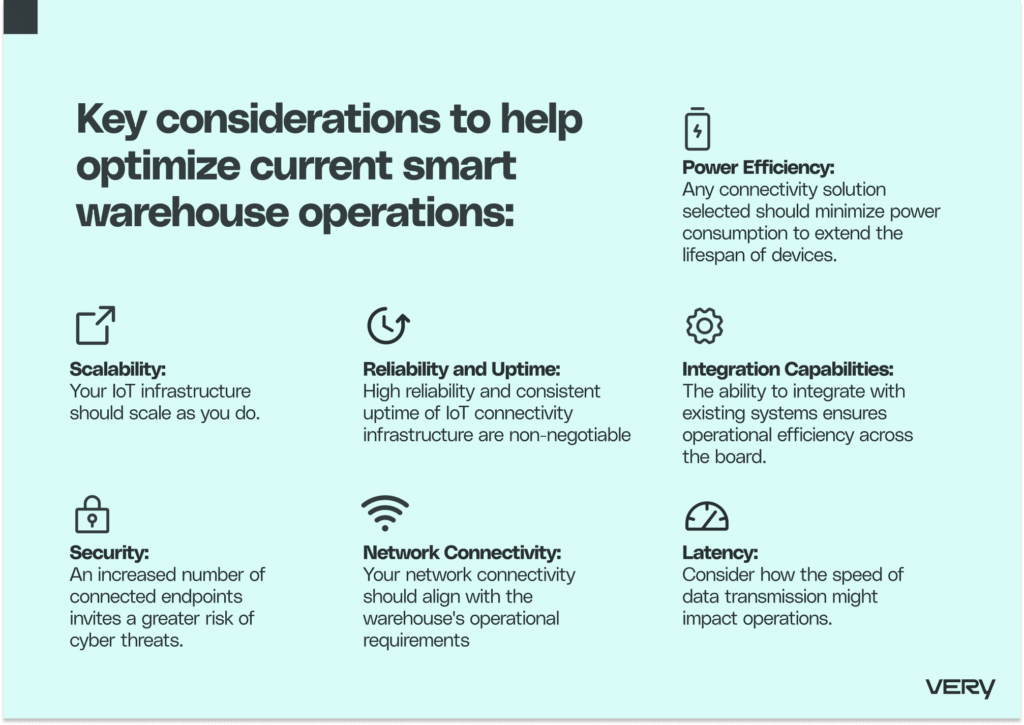

Here are some key considerations to help optimize current smart warehouse operations and prepare warehouses for future business needs.

- Scalability: Your IoT infrastructure should scale as you do. Connectivity solutions should support an increasing number of devices and data volumes without compromising performance. This means considering future growth in the initial design to avoid costly overhauls down the line.

- Reliability and Uptime: High reliability and consistent uptime of IoT connectivity infrastructure are non-negotiable to maintain operational efficiency and meet delivery timelines.

- Network Connectivity: Whether it’s cellular, Wi-Fi, LoRaWAN, or a combination thereof, your network connectivity should align with the warehouse’s operational requirements, including range, bandwidth, and power consumption needs.

- Security: An increased number of connected endpoints invites a greater risk of cyber threats. A secure connectivity framework is essential to protect sensitive data and maintain the integrity of the warehouse’s operations. This includes encryption, regular updates, and secure access controls.

- Integration Capabilities: The ability to integrate with existing systems (like warehouse management systems) and other applications ensures operational efficiency across the board. Seamless integration enhances data accuracy and operational visibility for faster, more intelligent decision-making.

- Power Efficiency: Many IoT devices in smart warehouses are battery-operated, which means power efficiency shouldn’t be overlooked. Any connectivity solution selected should minimize power consumption to extend the lifespan of devices.

- Latency: Consider how the speed of data transmission might impact operations. For example, low latency connectivity is essential for applications like autonomous guided vehicles (AGVs) and real-time inventory tracking.

We’re only scratching the surface of IoT connectivity, but these considerations are a good first step in building a robust connectivity architecture that meets the needs of your smart warehouse—today and tomorrow.