BLOG

How to Use Batteries to Power IoT Devices

In August of 2019, there were 26.66 billion active IoT devices worldwide. These devices are deployed everywhere from remote areas of the world to the television in your house. With continued growth in IoT projected for the foreseeable future, it seems a logical question to ask, “How are we going to power all of these devices?”

The answer to that question isn’t quite that straightforward. The technology’s deployment location and purpose will largely dictate the physical size as well as the required electronics. These considerations must also be balanced with cost. All of these things, in turn, inform the ideal power source for a given application.

An IoT product may require a small amount of power for something like a small RF beacon, or a relatively large amount of power for a gateway doing some basic edge-computing tasks. In the latter case, a dedicated power supply that plugs into AC mains might be required. In applications where portability or size is restrictive, or if AC mains are unavailable, it is difficult to get away from batteries. Using rechargeable batteries with a renewable energy source is often the ideal solution for powering remote deployments where maintenance is difficult and costly.

However, there is more to selecting the right power solution for your IoT application. It’s not enough to pick a battery that simply powers your electronics. It’s important to pick a battery that also powers your electronics between charges, fits mechanically, is environmentally compatible with intended deployment locations, and is cost-effective. In this blog, we’ll dig into what exactly a battery is and look at things you need to consider when powering your IoT system with batteries.

What is a Battery?

Very generically speaking, a battery is anything that stores energy in one form that can be converted into another form to do work. As an example, pumped hydroelectric storage could be considered a form of a battery. There are even newer ideas using stacked concrete blocks that would provide batteries for locations where pumped hydroelectric storage is unavailable. In both cases, the battery is charged when excess energy is being generated, and then gravity serves as the fuel when energy demands spike. While these technologies might be ideal to replace lithium-ion batteries for grid storage, coud you imagine a concrete block tower on the hood of your car or in your backyard?

For most people, the two examples above likely don’t come to mind when the word battery is used. What immediately comes to mind is probably a chemical battery such as a standard AA alkaline battery, or the lithium-ion battery powering the cell phone on which this blog is being read.

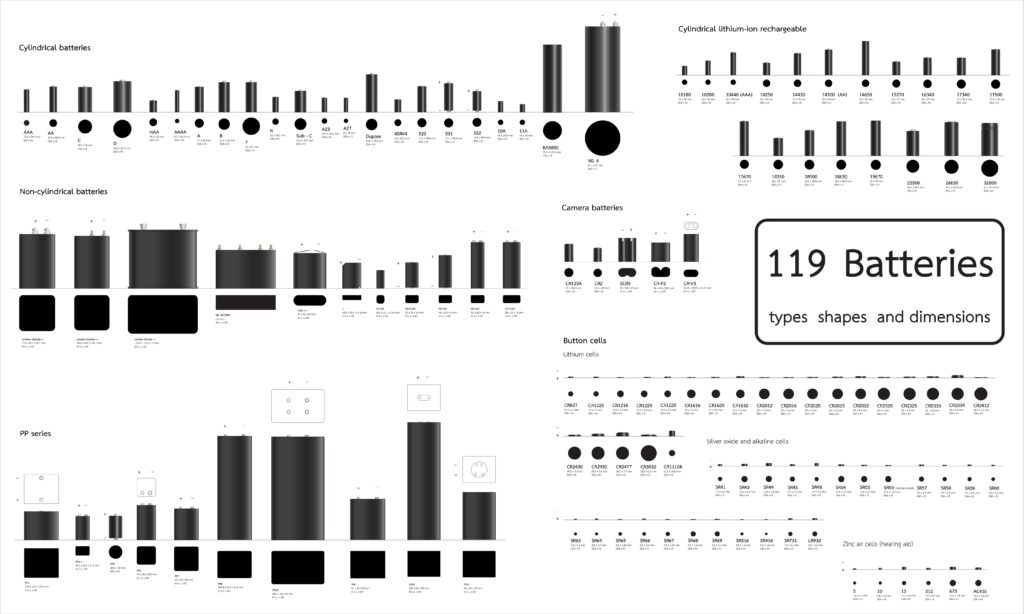

Batteries can be largely grouped into primary (non-rechargeable) and secondary (rechargeable) categories. The key difference between the two is that in secondary batteries, the chemical reaction can be reversed to recharge the battery.

Why Lithium-Ion Batteries for IoT?

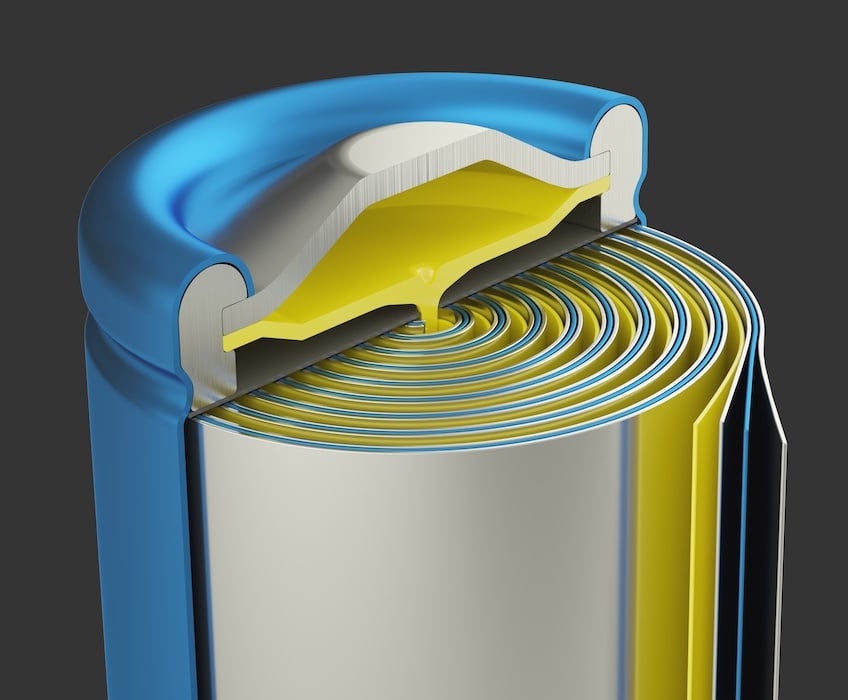

The image above is a cut-out view of a typical Li-ion cylindrical battery. Chemical reactions occur at both the positive (yellow) and negative (blue) electrodes. This gives rise to the voltage of the battery. It also produces electrons which power the external electronics. The electrodes are rolled together with a separator in this or other geometries to get the desired voltage and energy combinations required for different applications.

Given how prevalent batteries have become within society, it seems crazy that the Nobel prize in chemistry was only just awarded in 2019 to the three gentlemen who revolutionized the lithium-ion (Li-ion) battery. The work of John B. Goodenough, Akira Yoshino, and Stanley Whittingham paved the way for a countless number of applications, and, quite arguably, the IoT revolution itself.

If you’re reading this, there’s a good chance you are taking part in that IoT revolution. And if your “thing” does wind up being battery powered, it will most likely be by a Li-ion battery.

Li-ion batteries have become the preferred power source in most applications because they offer the best combination of power available per unit mass and volume. Not to mention, they have the highest coulometric efficiency. Put another way, for every Watt of power put into a Li-ion battery you get the most power back out. Lastly, a single Li-ion cell operates nominally at 3.7V. This is above 3.3V which is one of the most common logic levels used in electronics today.

Things to Consider When Powering IoT Devices

Knowing how much Li-ion batteries have going for them, the obvious question is then, “Why are these other types of batteries even used anymore?” As in most things in life, there are different factors that inform a decision, and there are non-ideal solutions that can become ideal given the right set of circumstances.

1. Temperature Performance

One of the most impactful parameters on battery performance is temperature. At lower temperatures, battery chemistry begins to slow down, which decreases the available power. Most batteries are unable to provide the full power they would at room temperature, but not all battery chemistries “feel” this equally.

Lead-acid batteries can provide more energy at lower temperatures than Li-ion, which is why they are still commonly utilized in the automotive and grid storage industry. Nickel-cadmium batteries are better suited for low-temperature operation. However, as with other nickel-based batteries, they are prone to high self-discharge. It is also highly advisable not to charge any battery at low temperatures, as this can permanently damage them.

Likewise, when running at high temperatures and/or high loads, batteries can begin overheating and enter thermal runaway. It’s unlikely that a battery is going to burst into flames or explode unless the gas release mechanism is faulty, but explosions can and do occur in extreme situations. More likely, it will spew out a bunch of incredibly toxic gas, which is obviously not a good outcome for anyone involved.

At either end of the temperature range, there are methods to keep batteries within safe operating temperature ranges. However, this ultimately comes at the expense of overall system efficiency, as a fair amount of energy can be spent on heating or cooling the batteries themselves.

2. Other Environmental Factors

Depending on the nature of an IoT application, there may be additional environmental factors a product must withstand. Salt sprays and humidity are common considerations for deployments near the sea.

In some cases, chemicals or other liquids are being used as part of the manufacturing process that the electronics may be controlling. The chemicals may be harmful to the components of the battery directly, or they may be conductive enough to short the battery terminals. Either of these could potentially lead to thermal runaway.

3. Power Budget

The power requirements of any given application are the most impactful on power source selection. Things like the cost and availability of different power sources also inform this decision.

For example, if the cost of the battery required to provide the power is so high that the system is unaffordable for its application, then other power sources should be considered. If mobility is required, then Li-ion batteries or energy harvesting are much more viable sources. If AC mains are both unavailable but lack of mobility is not an issue, say for remote back-up grid storage for a solar power network, then lead-acid batteries become more attractive primarily because of up-front cost and improved low temperature performance.

It is well outside of the scope of this blog to discuss power budgeting. However, if you are developing an embedded application involving PCBAs, a good guide to follow can be found here. For larger systems, a very similar process can be followed – you’d just replace the individual integrated circuits (ICs) with the larger system.

4. Form Factor

Given a set of environmental and power constraints, the mechanical size and mass of your product are also important to consider. In automotive applications, there is typically enough room for a larger battery to power electronics in a low-power mode until they are charged again.

There are also other places to shave off a bit of weight in that application. In a cell phone or laptop, however, days or even hours of run-time are needed in something that is carried around in someone’s pocket or bag. The size and weight are critical. Taking this to the end of this extreme, in many sensor applications there is only enough room for the electronics and power source required to monitor a specific property, such as temperature, and transmit the data to a hub. In this case, coin cell batteries such as the standard CR2032 are often the best choice.

5. Monitoring the State of the Battery

Overcharging or over-discharging a battery can likewise be detrimental to its overall health. Overcharging a battery can lead to gas formation and corrosion. Over-discharging a battery can cause plating to form on the electrodes, which ultimately slows reaction rates and contributes to increased internal resistance. This can drastically reduce the expected lifetime of a battery.

In order to maximize the investment in your power solution, it’s best to monitor the state of charge (SOC) of the battery. There are two ways to do this. If properly utilized, tracking SOC over time will also facilitate more accurate prediction of the overall state of health (SOH) of the battery.

The easier and more cost-effective solution is to monitor the battery voltage. This is like measuring the height of the water in a water tower to track how much is left. It tends to be less accurate, and it can become expensive to improve the accuracy. However, it might be appropriate in certain situations where you need to start something that can then charge the battery back up.

The other method is called coulomb (or charge) counting. You can think of this like monitoring the flow of water out of a tower over time. It allows you to track exactly how much water, or charge, has left the tower, or battery. The amount of charge that has left or entered the battery is continually subtracted (or added) from the starting amount, providing a more accurate way to track SOC.

For devices that run at lower voltages (<12V), there are “gas gauge” ICs from Texas Instruments that will both do the coulomb counting, monitor battery conditions, and, if necessary, open the discharge/charge path. There is other circuitry required in order to fully implement them. From the price standpoint, you are looking at a few cents per device for the voltage monitoring method, but it could easily be up to $5 or more of components to monitor the current.

Whatever method you choose, below are some very general tips to prolong the expected lifetime of a battery. Be sure you understand how to set the appropriate limits (like the minimum voltage, short-circuit current thresholds, etc) within your SOC monitoring solution. Consult with the device manufacturer for more information.

- If possible, always operate the battery at room temperature. Just like you and I, batteries are most comfortable in this temperature range.

- Charge and discharge the battery slowly. When charged or discharged at high rates, side reactions occur more rapidly, which degrades battery lifetime.

- In most cases, never fully discharge a battery. In Li-ion batteries, full discharge can cause plating to form on the electrodes.

- Be sure to understand any requirements of your specific battery. For example, some nickel-based batteries require routine maintenance in the form of a complete discharge.

- The lower your depth of discharge (DOD), the better. (DOD is the battery life percentage displayed on your cell phone.) If your charge/discharge cycle stops at 20% DOD (as compared with 80%) the expected cycle life of some batteries can be in the tens of thousands.

6. Shipping and Product Compliance

What’s a good blog with a discussion of everyone’s favorite topic? Logistics and product compliance!

In all seriousness, however, this is something that is often overlooked. Don’t worry – this is only a mention of compliance. but it is incredibly important. When shipping batteries alone, there are often more strict rules in place than when the battery is contained within a product. In the case of Li-ion in particular, when they are contained within an electronics assembly there are seldom any issues, but when shipping them alone they are considered hazardous materials. Regardless, it is advised to ensure that both you and your supply chain are following all the necessary regulations when shipping anything containing products. UPS has put together this helpful guide that is a good starting point.

Powering Your Next IoT Project

As you look at power options for your IoT product, this blog should provide you with some reliable tips to get you started. If you’re looking for an expert team who can help you make these kinds of complex hardware decisions, reach out to Very today and tell us more about what you’re working on.