BLOG

How Is Data Science Used in Manufacturing?

Data science and “big data” continue to be hot topics, and for good reason.

With the exponentially increasing number of Industrial Internet of Things (IIoT) devices, pulling data from these connected devices and sending it to manufacturers is becoming increasingly important. Manufacturers and operators can use this data for a variety of high-value purposes. In this article, we’ll address four important ways that we see data science transforming the manufacturing industry: predictive maintenance, market price analysis, demand forecasting, and warranty analysis.

1. Data Science Powers Predictive Maintenance Programs

Perhaps the most prominent use of data science in manufacturing is for predictive and preventive maintenance. Data scientists use data from a variety of sensors and track that data against the optimal reading to determine if a piece of machinery is about to fail.

Contrast this with reactive maintenance, where maintenance activity takes place after the disruption has occurred, or scheduled maintenance, where plants follow a predetermined inspection and repair schedule, regardless of how the machine is performing.

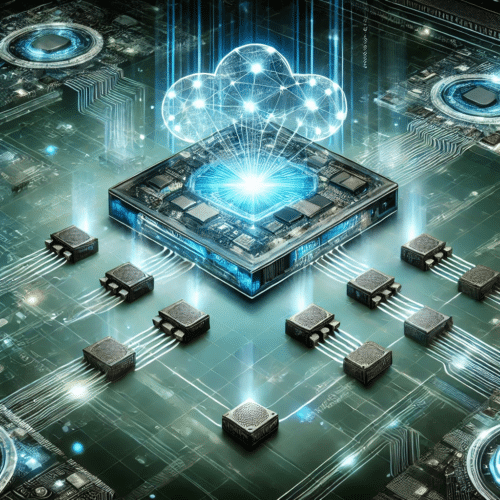

With predictive and preventive maintenance, modern machines, or legacy machines retrofitted with IoT capabilities, collect data through sensors mounted in various places along the production line. These sensors are devices that measure changes in physical phenomenon (temperature, pressure, movement, etc.) and translate them to electronic signals. Sensors typically send the data they collect to the manufacturer or operator in a central hub, either in the cloud or an on-premise server.

After that, the data scientist interprets that data through predictive modeling. These models determine whether the machine is about to have a breakdown and what action you should take to manage it most effectively.

For example, say a piece of equipment is determined to have a deficiency that will impact the manufacturing operation soon. Of course, you could proactively repair the part, but is that the most efficient use of your resources? Are there adjustments you can make to the hardware that would be more cost-effective? Alternatively, maybe there are more maintenance costs associated with fixing the part than with replacing it altogether, depending on the structure of your operation. Your business goals should drive the resolution method.

2. Data Science Helps Predict Market Pricing

Product prices constantly fluctuate as price drivers shift – whether it’s due to seasonality, the demand for the product, or limited availability. Determining the optimal price for the product you manufacture by analyzing past, current, and future market prices will increase your margins dramatically. Data scientists can use machine learning to predict these optimal prices.

Machine learning approaches like decision tree-based ensemble methods (using multiple base models to improve predictive performance rather than relying on just one), as well as deep learning methods for predictive modeling, enable data scientists to build models of potential future pricing. By applying univariate (using a single input) and multivariate (using multiple inputs) time series prediction and forecasting to these models, data scientists can anticipate changes in market prices and make recommendations on the next best action for the business to take.

3. Data Science Is Key To Forecast Demand

Properly forecasting demand will determine your optimal supply rate, minimize unnecessary manufacturing or inventory holding costs, and streamline your supply chain.

If the demand for a product suddenly rises and you can’t keep up with the demand, the missed sales opportunities impact your bottom line. On the other side of the coin, sitting on giant inventory stocks that you can’t turn at an optimal rate isn’t great for business, either. Forecasting demand is a key component in keeping your manufacturing on target.

As with all data science projects, the quality and cleanliness of the data will make all of the difference in the outcome. If your CRM or ERP is unreliable, or if your POS systems are used inconsistently throughout the business, it is likely your predictions will be unreliable and inconsistent, too. Your first step in those cases will be to clean up the data.

After cleaning the data, data scientists can build complex machine learning models and applications that analyze historical demand data from sales, marketing, and financial sources (e.g. CRM, ERP, POS systems, market studies, and more) to make reliable predictions about future product demand.

4. Data Science Powers Analysis of Warranty Claims

Manufacturers stand to lose a considerable amount of money on warranty claims, not only in payouts for defective products but in lawsuits and brand damage if a malfunctioning product causes injury or makes the news.

Ideally, your products would ship and operate perfectly up until their warranty date and beyond. Practically, however, we know that’s not a realistic outcome. Product issues will occur, and claims will be made. Innovative companies look at every claim made as an opportunity to improve.

Manufacturers can use data science to create a system for analyzing the data with every warranty claim that comes in to determine if their product is having issues in the same areas time and time again. Manufacturers can then determine the root cause(s) of the product issues and iterate on the design of the product to lessen the number of warranty claims that come in, and in turn, increase their product and customer satisfaction.

Data Science Will Help You Adjust to a Lean Manufacturing World

Data science is disrupting manufacturing in a big way right now. Even established manufacturing companies have adopted the practice to keep up. Lean manufacturing is the “norm” now, which causes companies to adopt continuous improvement programs at every stage to eliminate waste.

When done well, data science results in increased productivity and profit. To be successful, however, you’ll need to make sure that your data science team asks the right questions, and then determines and collects optimal metrics to help you meet your business goals.

Going further, you need to present the insights to end users who can use the predictions and recommendations to make more effective decisions. You may integrate this information into existing systems or build a stand-alone application dashboard to share the relevant data. At Very, we find it particularly effective to develop these applications with data scientists working as integrated members of a full-stack Industrial IoT development team.

With data science, manufacturing companies can create, price, and distribute products as efficiently as possible. This newfound efficiency will translate into improved competitiveness and an increased bottom line.